Here’s the thing about a garage floor coating: it only sticks around if the concrete underneath is readied. You can buy the best coatings on the market, but if the prep work isn’t right, it’s like trying to put tape on a dusty wall—it just won’t hold.

That’s why proper concrete prep is the most important part of the whole job (…along with selecting the right primer coat).

What the CSP Scale Means

The big factor here is called the Concrete Surface Profile (CSP). Think of it as a scale that measures how smooth or rough the floor is. CSP 1 = smooth like glass; CSP 10 = rough like sandpaper on steroids. The sweet spot for a garage floor coating = CSP 3–4

But why does this matter? A surface that’s too smooth won’t give the concrete coating anything to grab. Too rough, and you’re making the job harder than it needs to be. Right in the middle—3 to 4—is where you get a solid bond that lasts.

What Doesn’t Work

Some prep methods sound fine but just don’t cut it. Here are a few of them.

- Acid etching → leaves the floor too slick

- Water jetting → same problem, too smooth for long-term bonding

- Sandblasting or rotomilling → overkill for garages, creates too much texture

These approaches either make the surface too weak for a garage floor coating or go way past what’s needed.

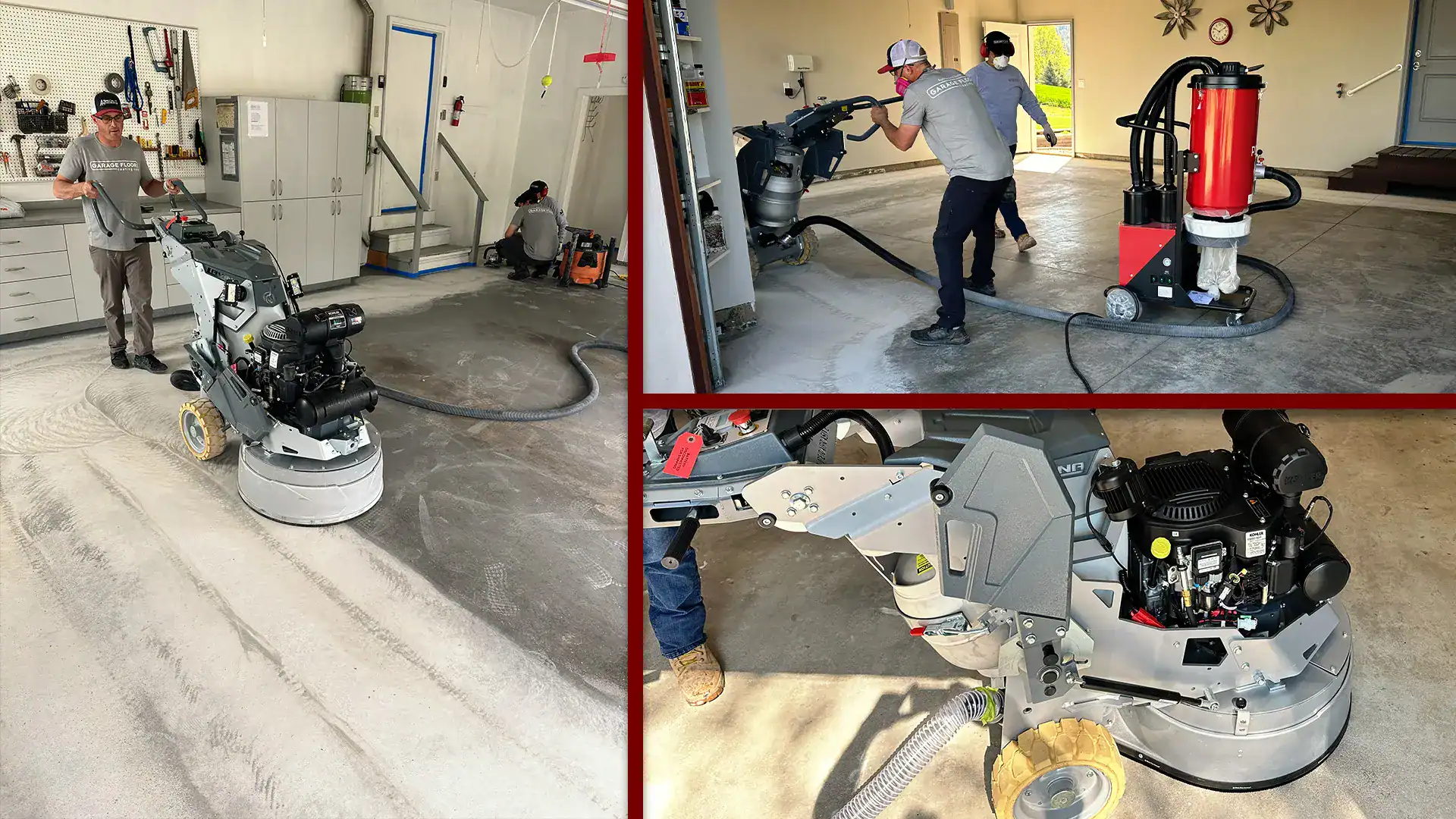

The Better Way: Grinding

Grinding is the go-to because it lands right in that CSP 3–4 range. But even here, the type of grinder makes a big difference.

- Electric grinders → smaller, cheaper, but slow and less powerful, limited and unsafe in wet or damp spaces

- Propane grinders → stronger, faster, and cover more area without cords

That extra power and efficiency means the prep work gets done right—and done quicker. We obviously love propane grinders, and with near-zero emissions they’re great even in tight, indoor spaces. If you’re worried about the word ‘propane,’ fear not! It has an extremely high-temperature range of flammability, which makes it a lot different from the gas in your car.

Why This Matters in Tucson

Tucson garages see a mix of heat, dust, and heavy vehicle use. If the surface isn’t prepped properly, that coating is going to start peeling or cracking before long. But with the right CSP and proper grinding, the garage floor coating bonds tight and can stand up to the local conditions.

Wrap-Up

At the end of the day, the secret to a great garage floor coating isn’t really a secret—it’s making sure the concrete is prepped the right way. Hitting that CSP 3–4 range with a propane grinder sets the whole project up for success. If you’re ready for a garage floor coating that won’t let you down, start with solid prep and the rest will fall into place.