Tucson’s dry climate makes it easy to believe moisture is not a concern. But every concrete slab contains moisture. The real issue is not whether moisture exists. It’s whether a polyurea garage floor coating system is engineered for moisture mitigation, or designed to blame the slab after failure.

Polyurea “Limits” That Quietly Void Warranties

Many 1-day polyurea installers rely on numbers like a maximum Tramex reading or a low MVER threshold. These figures are often presented as industry standards, but in practice they function as warranty escape clauses.

Installers frequently skip proper pre-install (baseline) moisture testing or documentation. When a garage floor coating eventually blisters or peels, a moisture reading is taken directly at the failure point where vapor pressure is highest. That elevated number is then used to deny coverage. Homeowners are left with a failed coating and no recourse.

Why 1-Day Polyurea Installations Let Moisture Win

A speed-focused polyurea installation typically uses fast-curing polyurea or polyaspartic primers applied directly to concrete. These materials cure quickly, but they do not provide true moisture mitigation.

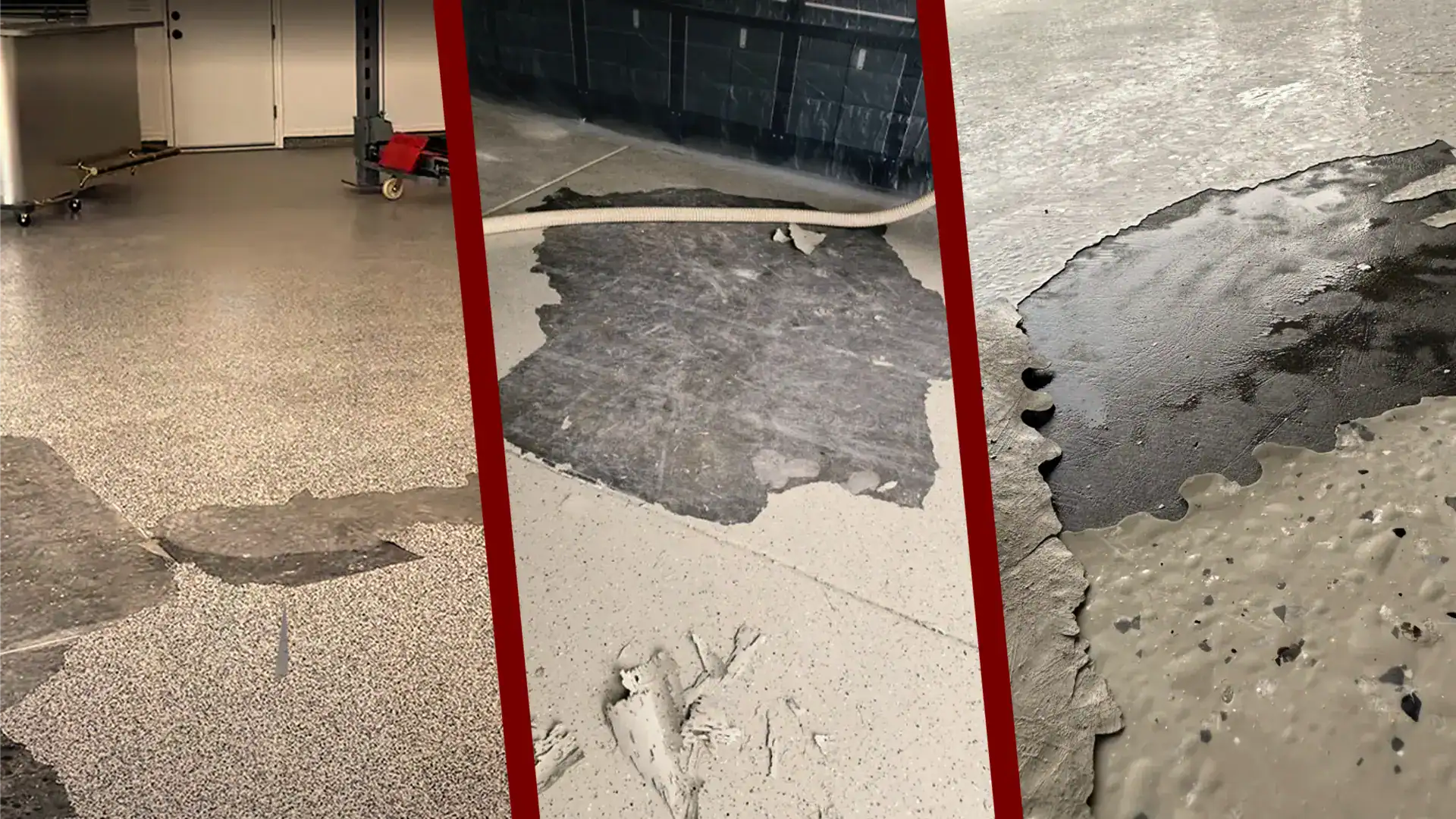

Quick cure does not equal vapor control. Without a moisture-mitigating base coat, natural Moisture Vapor Transmission pushes upward through the slab. In Tucson, irrigation, seasonal rainfall, and ground moisture still drive vapor through concrete. When pressure builds beneath a coating that cannot manage it, blistering, peeling, and delamination follow.

Polyurea Myths Versus Concrete Reality

Moisture is not a coastal or humid-state issue. It is a concrete reality. Concrete absorbs and releases moisture continuously, regardless of climate. A polyurea system that treats moisture as an exception is relying on ideal conditions that do not exist in real garages.

When coatings fail, moisture gets blamed. In truth, the system was never designed to coexist with moisture from the start.

Our Garage Floor Coating Systems Begin With Moisture Mitigation

GarageFloorCoating.com (Tucson) installs garage floor coating systems built for long-term adhesion. First, we start with an industrial, 100% solids epoxy primer engineered for moisture mitigation, creating a chemically bonded foundation within the slab.

Secondly, we broadcast your chosen decorative flake blend across the entire floor in a full flake spread for added texture and strength. Lastly, on Day 2, we apply two 100%-solids polyaspartic clear topcoats for durability, UV stability, and easy maintenance. This process requires a professional 2-day installation so each layer performs as intended.

If you are considering a 1-day polyurea install, ask the contractor what layer provides true moisture mitigation, then schedule a consultation with GarageFloorCoating.com (Tucson) to get a system built to last. And explore colors and flake blends using our Live Coatings Visualizer to see how a professionally installed system can look in your garage.